Articles #1 | Case study: Dentec - 3D industrial animation as a promotional video for trade fairs

In this project we have been challenged to prepare 3D industrial animation working as a promotional video being shown at trade fairs by Dentec - Polish company specialized in designing application-dedicated grippers for robots. If you are interested in having your machines animated, follow the article below to find out about all the steps of animation designing process, set goals and final result we achieved.

Dentec is an innovative, fast-growing, young company providing dedicated solutions to its industrial customers. They design vacuum grippers for arm robots and prepare fully automated machines combing techniques of computer vision, precise manipulation and others. At the same time they are exclusive distributor of one of the market leader in vacuum technology components, FIPA Gmbh company.

At the roots of the project we agreed to put stress on two main goals to be achieved by the animation:

present Dentec as a reliable company experienced in gripper design for robots

expose information about cooperation between Dentec and FIPA, worldwide known, decent business partner

What we received from customer were CAD models of ABB robot, injection mold and designed gripper. Customer also prepared short description of crucial parts they want to have shown in the animation. We got also information that “matrix style shoots” are highly appreciated 🙂

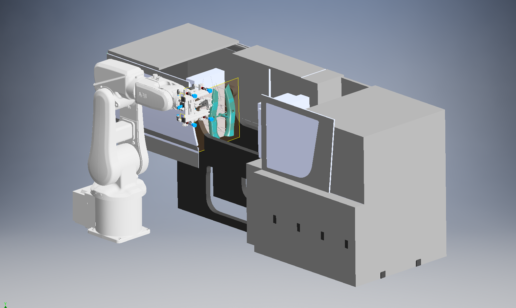

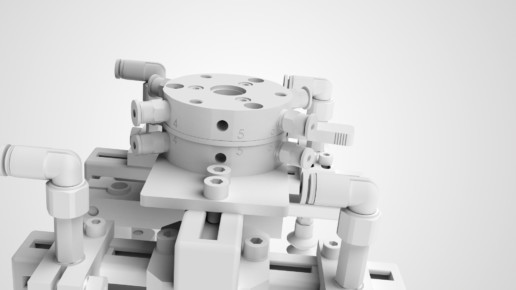

Fig. 1 Raw CAD model we got from customer

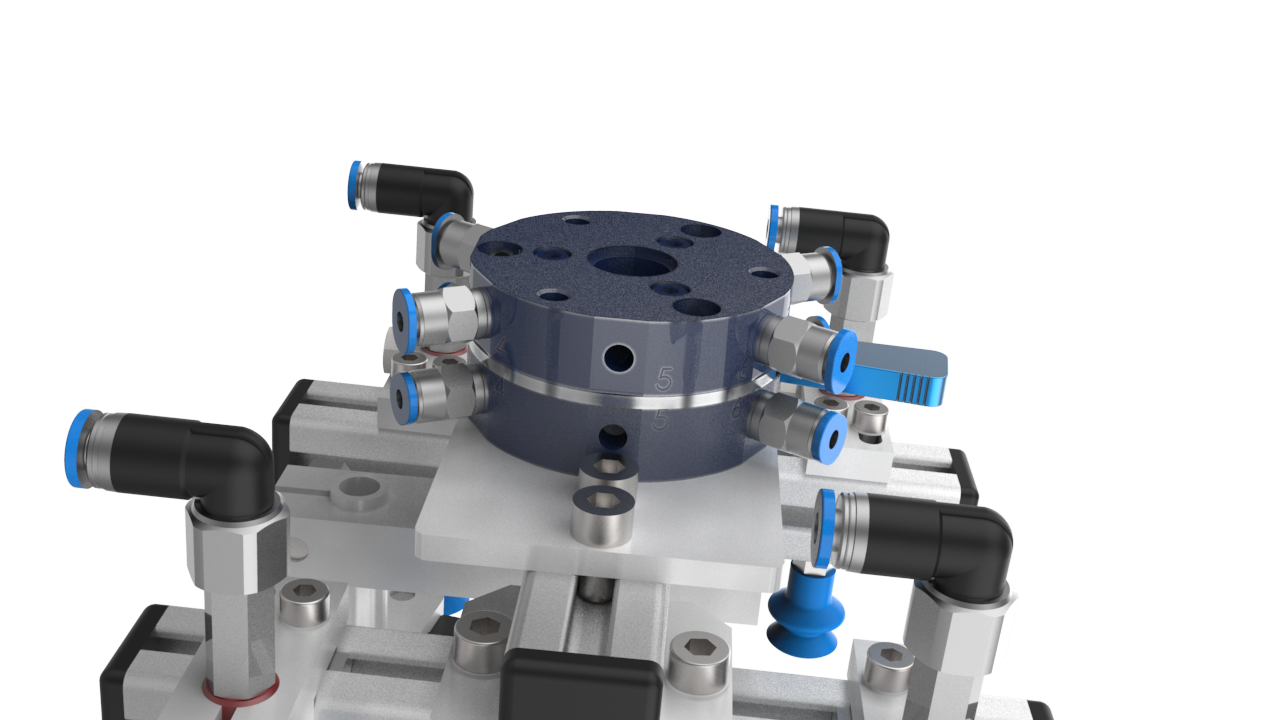

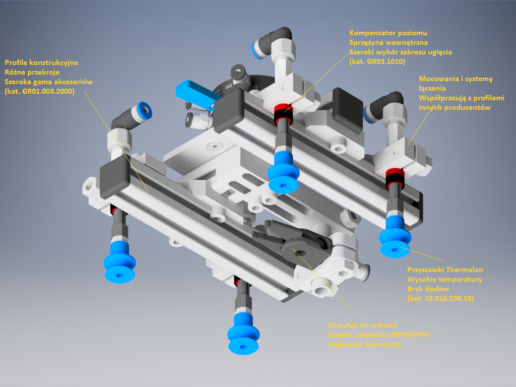

Fig. 2 The gripper with customer’s annotations pointing crucial elements of the project

Togheter with Dentec sales specialists we decided to split animation for two main parts. In the first half of the project we were supposed to present process of reception molded part from the injection molding machine. In the second one, we focused on the gripper itself and FIPA components it had been built from.

To achieve these goals we started with 6-axis ABB arm robot movement simulation done in CAD softwere. That was crucial to perform real relationships between all the axises.

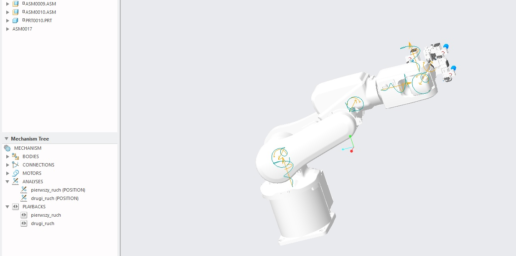

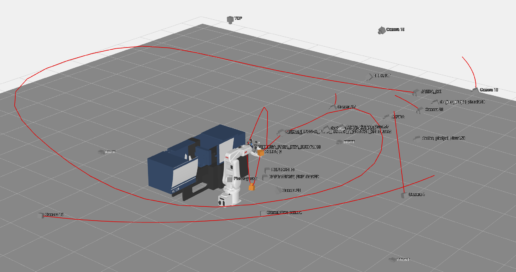

Fig. 3 Definition of all virtual motors needed to prepare simulation of six axis ABB robot’s real movements

In the next step we started working with rendering software. That was the most relevant part of the project. Firstly we had to set all camera angles with its changes and initially adjust lighitng settings. Then we designed all the movement’s of the other model’s parts moving in the animation.

Fig. 4 Simulated movement of the robot imported to rendering software

Fig. 5 One of the detailed camera shots pointing at specific part of the gripper

Fig. 6 Gripper’s exploaded view camera shot

Fig 7. Scheme of the cameras used in the project

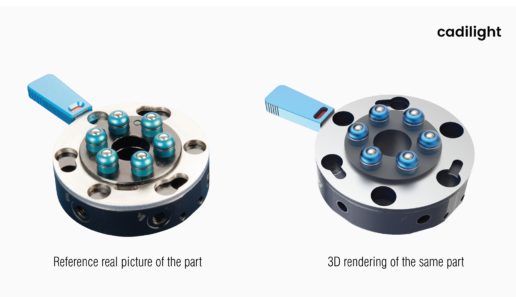

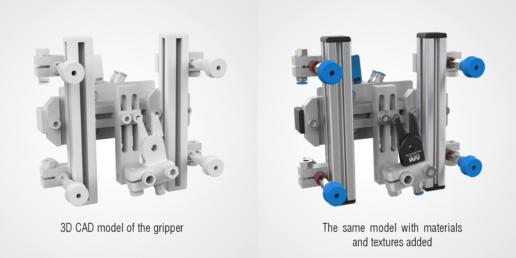

In the next step we set all the materials in the project. That includes type of material, textures, labels and parameters like roughness and many others. In industrial animation design we have to very precisly define all the materials. That refers also to the parts appearing only for a very short period of time in the final animation.

Fig. 8 Comparison of digital image of real part used in the project and 3D rendering of the same part

Fig 9. Comparison of 3D visualisation of the vacuum gripper without and with materials and textures

Fig. 10 Exploaded view animation

The last step of our work was post-production process. Beasically, that was about adding callouts pointing specific parts of the gripper and final animation of Dentec logotype.